What can quality management do for your wind project?

Do completed wind project works meet all the requirements of the contract as well as project specifications, permitting requirements, laws, and regulations after the construction?

This is an essential question for any project owner. Not only during the development and contracting phase but also during construction and after commissioning. After all, any deviation from specifications can directly or indirectly affect your business case. Accurately monitoring the quality of all project aspects prevents problems and contributes to a more efficient project process.

Ventolines monitors the quality of your wind project while minimizing the associated costs.

What is quality management?

Quality management includes all activities necessary to achieve the highest level of quality.

- Drafting a quality policy

- Quality planning and assurance

- Quality control and improvement

Wind projects require quality management throughout the project life cycle.

The goal is to verify that the manufacturer and contractor comply with the requirements in the contract, permits, laws, and regulations. In addition, excellent quality management ensures your project renders optimal return on investment by having the wind turbines provide the maximum yield.

Damages

Quality management identifies damages in time, allowing a temporary construction stop. This way, repairs can be completed immediately that would be impossible to complete further in the construction process. (Example: the grounding cables in the anchor cage can only be checked before pouring the concrete foundation.

Repairing damages at a later stage can create additional costs

- The turbine must be shut down during the operational phase, resulting in lost revenue;

- Repair costs are generally higher when the turbine is already fully operational;

- The contractor tries to pass on the construction damage costs to the operational phase, recovering repair costs from the client.

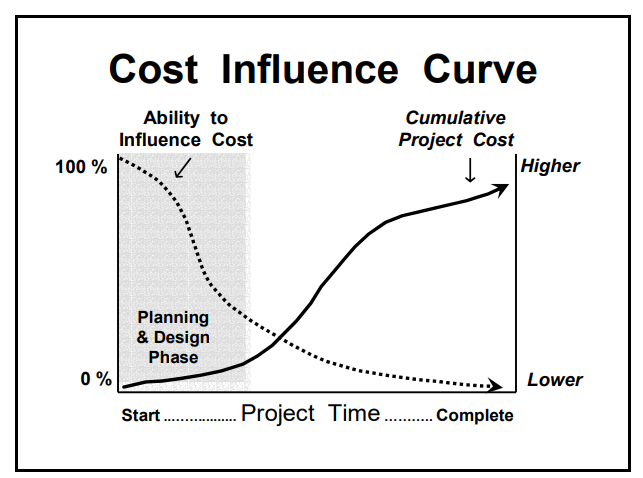

The diagram above shows that the ability to influence costs is more significant in the early planning and design phase. As the project progresses, cumulative project costs will increase, and the ability to control these costs will decrease.

Quality management begins during project development

Quality management starts during the tender phase with comprehensive monitoring of quality requirements. Mutual agreement on definitions and processes will further facilitate the quality control process. We always recommend thoroughly vetting and inspecting (if possible) wind turbine suppliers in the early stages of a tender. This way, we discover whether a supplier can meet your requirements and identify any risks as soon as possible. We can then reduce and monitor these risks during your project.

What documentation is required for your quality assurance plans? project-specific quality management plans? inspection and test plans? general documentation and data management requirements?

- Your rights to witness and hold points and assessment of specific processes to implement your quality control plan;

- How to handle desin changes and non-conformance to avoid lengthy discussions afterward;

- How you want to receive quality reporting from the contractor to track progress.

To ensure that quality management functions properly during the production and construction of your wind turbines, it is essential to have clear agreements on these processes with the wind turbine supplier before signing the contract.

What can Ventolines do for you?

Our inspectors conduct quality inspections using our intelligent, automated systems. One such system is our award-winning application, ‘Gemba‘. It allows us to quickly record ad hoc quality observations on-site and archive them automatically. In addition, scheduled inspections are performed with another automated application, which increases inspection and reporting convenience.

Experience shows that with our smart tool systems, our inspectors spend significantly less time on administrative work, leaving more time for physical quality control at the construction site. The resulting metadata provides detailed input for discussions with the turbine supplier.

Discussions on quality issues with the turbine supplier are conducted through a clearly defined system, assigning the issues to the appropriate management levels: operational level, work package level, or, if necessary, senior management level. This clear separation of primary and secondary issues enables increased efficient use of the experts’ time.

Use the form below to let us know how we can help your project.