Gemba Observations

Ventolines aspires to become a safety leader in the renewable energy industry. We are convinced that the Gemba Observations application will play a major role in this objective, as it allows us and our clients to have a clear understanding of the QHSE issues that apply to their projects.

Gemba Observations is a QHSE observation application used to report progress, (un)safe conditions, incidents or quality issues. The Gemba app is part of Ventolines and is a great example of how Ventolines applies modern technology to control sustainable energy projects. This application gives all project members an up-to-date overview of the progress, quality and QHSE status of the project. This information is used to identify follow-up steps and actions and is discussed in contractor, stakeholder and internal meetings.

The goal

Gemba has a clear purpose, reducing the time to act on trends and QHSE concers while improving a project’s QHSE performance. We think it should be possible report QHSE observations within 30 seconds, since this lowers the threshold for reporting. With the Gemba application, these observations help create detailed trend analyses. QHSE observations contain a lot of knowledge and information about projects, which is why we wanted to give users access to this data. Our interface with Sharepoint and Power Bi shares valuable insights automatically and quickly.

Benefits of using Gemba

-

- Increased involvement of “office or staff” personnel in the project

- Increased participation of the workforce in reporting QHSSE observations

- Reduced threshold to report “minor” QHSSE improvements

- Increased awareness by senior management, and project manager in the actual QHSSE findings on site

- Shorter time required to identify situations and take the required action

- Reduced costs compared to developing and operating a company specific application

How does it work?

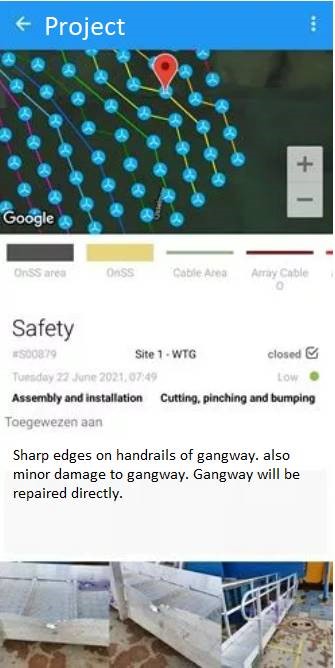

The application can be found in the application store on your mobile device. Users can choose from five types of incidents: safety, environment, quality, security or progress. Observations can also be specified on activity, danger and criticality. The location of the observation can be entered manually, or automatically with the help of a GPS function. User can select one of multiple stages of a construction project. These categories are related to the categories used in the annual QHSE report provided by the global G+ organization. The purpose of this alignment is to be able to provide more information towards global HSE organizations that are also involved in setting new industry HSE guidelines.

Gemba Observations as a system

The Gemba application provides us clear insight of the QHSSE issues that are apply to our clients projects. The system is set-up to not only analyze each project independently but also analyse trends. These trends help us identify the QHSSE challenges of the industry during the different phases of a project in the renewable energy sector. The results of our analysis can be used to identify specific improvement areas that can be used during the tendering, preparation, construction and operation phase of a renewable energy project.

One database for all information

All information that is gathered by inspectors in the field is collected in a database. This database has API connections to Office 365. We will create a real-time issues list in Sharepoint that contains all notified issues, including pictures, based on the location details, report, activity, danger and criticality. This overview is used to follow up on reported issues and identify required actions by the contractor. This real-time, accessible and shared issue list ensure that the whole project team is informed about the current issues and required actions.

Request a demo

“Information plays a key role in ensuring a safe and successful project. Ventolines relies on the Gemba Observations application to document all QHSE information. With this application we are able to address project issues in a in a structured way and and use them to improve HSSE on the project”

– Marco Kok (QHSE Manager)